TM 5-3895-363-13&P

10.2 MONTHLY MAINTENANCE

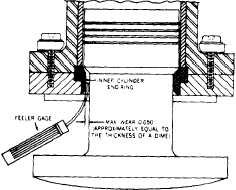

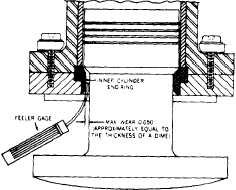

10.2.1 Check inner cylinder end ring clearance

(Fig. 22).

Figure 22

Drop impact block out approximately 5".

Run come-along around impact block and

lead and pull impact block towards the lead.

Measure clearance between inner cylinder

end ring and neck of impact block with feel-

er gauge. If clearance approaches 50/1000"

(1.25mm), replace inner cylinder end ring.

(See section 10.3.)

CAUTION:

Wear beyond 50/1000" (1.25mm) causes ex-

cessive wear on lower cylinder and even-

tually will crack the lower cylinder, and will

void warranty.

10.2.2 Check compression. Place hammer on an

already driven pile and make a cold blow.

Observe piston through pick-up slot on

upper cylinder. The piston should rebound

at least eight times (pronounced rebounds)

If not, change piston rings. (See section

10.3)

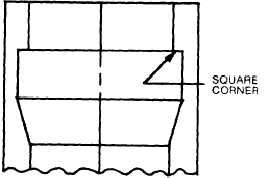

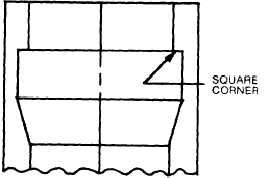

10.2.3 Check catch groove on upper cylinder.

Corners must be square (Fig. 23).

Figure 23

10.3 CHANGING INNER CYLINDER END RING,

PISTON RINGS, AND/OR RUBBER RING

IN VERTICAL POSITION

10.3.1 Block up drive cap on ground and detach

drive cap cables. Drive cap must be level.

10.3.2 Set hammer on drive cap.

10.3.3 Raise piston by means of tripping device so

piston barely shows at top of upper cylinder

(just as you would fill the oil chamber).

10.3.4 Remove oil plug and install eye bolt instead.

10.3.5 Attach second crane line to eye bolt (Fig. 24).

Figure 24

10.3.6 Carefully lower piston via tripping device

until the trip can be engaged to the lifting

blocks on upper cylinder.

10.3.7 Put strain on hammer line and piston line,

but do not lift the piston or the hammer.

10.3.8 Release piston from tripping device by strik-

ing the trip cam lever with a hand hammer

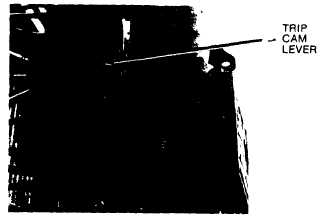

(Fig. 25).

10.3.9 Lower piston via crane line until this line

goes slack.

Figure 25

13